Hydraulic systems have become an indispensable element of modern industry and engineering, using oil-based hydraulic fluid to transmit motion and force and thus providing essential service across numerous fields – ranging from heavy manufacturing equipment and machinery, automotive systems, and aerospace platforms, with hydraulic systems playing an integral part in managing processes from heavy manufacturing machinery and vehicles to automotive and aerospace components. We will take an in-depth look into hydraulics’ uses within various fields; their function and well as benefits.

1. Introduction to Hydraulic Systems

Hydraulic systems are one subset of fluid power systems which encompass both hydraulic and pneumatic. While pneumatics rely on compressed air as their power transfer source, hydraulics utilize pressurized liquid (usually oil). Pascal’s Law states that when pressure is applied within an open system such as a hydraulic systems, pressure should be distributed equally throughout all directions – this principle forms the cornerstone for their functioning.

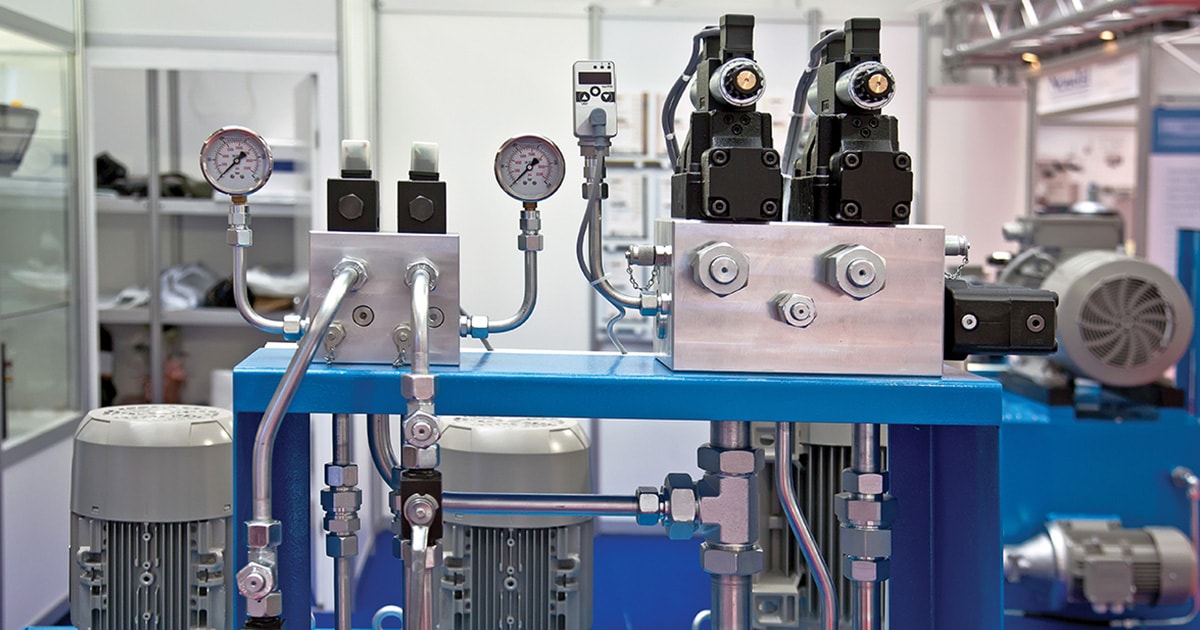

Essential elements of a hydraulics system include fluid, pump, motor (commonly referred to as “cylinder”), and valves – as well as pipes, hoses, and connections for transmission, control, and hydraulic power production. All these parts combine together for transmission, control, and hydraulic power production.

2. How Hydraulic Systems Operate

To fully comprehend their benefits and uses, understanding how hydraulic systems function is key. Here’s an in-depth step-by-step guide that describes some of the processes at work within these systems of hydraulics.

Hydraulic Fluid

These systems typically employ hydraulic oil designed for specific use. Selection criteria includes its ability to withstand extreme pressure levels, lubricate parts efficiently and withstand heat; its presence within an enclosed system prevents contamination while guaranteeing consistent performance.

Also Read: The Pomodoro Technique: Why It Works and How to Do It

Pump

At the core of any system lies its Pump. As its primary role it produces pressure by turning mechanical power into hydraulic. Most hydraulic pumps are powered either with an electric motor internal combustion engine, or other power sources – when running they draw hydraulic fluid out from a reservoir before pressing to pressurize it before sending to its destination in the system.

Valves

Valves are essential elements that regulate fluid flow within an infrastructure system. There are various kinds of valves – directional control valves, pressure relief valves and flow control valves among others – used to manage movement direction, pressure relief relief as well as rate of flow regulation. These elements come together to regulate system fluid flows.

Actuators (Motors or Cylinders)

After hydraulic fluid has been pressurized, its energy must be converted to movement through actuators such as hydraulic motors or Cylinders. There are two forms of actuators used within hydraulic systems; hydraulic motors and Cylinders may both serve this function.

Hydraulic Motors use hydraulic pressure to generate rotational motion and are frequently found in winches, conveyor systems and heavy equipment.

Hydraulic Cylinders

2.5: Transmission of Force The incompressibility of hydraulic fluid guarantees that any force exerted to one end will be passed without loss to its opposite end, making the hydraulic system highly effective at sending power long distances as well as controlling large loads.

Control is one of the hallmarks of hydraulic systems. By manipulating valves, operators can precisely manage directions, speeds and forces exerted by hydraulic actuators – this level of control being particularly significant when applied in applications where precision and dependability are essential factors.

Hydraulic Systems’ Benefits

Hydraulic systems offer numerous advantages that make them popular choices across industries, making hydraulic solutions ideal choices. Here are just a few key ones.

Hydraulic Systems Offer High Power Density One of the main attractions of hydraulics systems is their superior power density, producing large forces with limited space requirements – perfect for manufacturing equipment, construction machines and aerospace systems that demand higher power outputs.

Hydraulic systems offer precise force and motion control via valve manipulations. By controlling the direction and speed of hydraulic actuator movement with precise control valves, operators can regulate movement with great accuracy for robotic applications that demand precise movements.

Hydraulic systems are known for their long-term reliability. If properly maintained, they should operate for years without major malfunction or loss, which is of particular significance in fields where downtime could cost significantly.

Hydraulic systems offer inherent security due to their slow operation speeds and limited heat production compared to other transmission methods for power. Furthermore, hydraulics systems can handle overload situations without creating disaster thanks to pressure relief valves and other safety mechanisms.

Hydraulic systems can be extremely versatile and used across numerous applications, from agriculture and construction, through aerospace, automotive and manufacturing industries – being tailorable to each specific need of each industry is also key for their flexibility.

Hydraulic components are designed for long service lives. When maintained regularly, hydraulic systems can outlive other power transmission systems resulting in significant savings for businesses and industries alike.

Hydraulic systems have long been recognized for their efficiency in transmitting power, with incompressible fluid nature helping reduce energy loss while cutting energy consumption in the process. Their efficiency ultimately results in lower long-term costs and energy use than alternatives like electrical motors do.

Also Read: what-is-encryption-and-how-does-it-work

Hydraulic Systems Offer Precise Motion Control

Hydraulic systems provide smooth and precise motion controls. Their fluidic nature helps minimize vibration and shock – an invaluable feature when used for heavy machinery or aircraft control systems, for instance.

Hydraulic systems employ pressure relief valves as part of their overload protection strategy, to release excess pressure when necessary and avoid damaging components within the system. If an overload situation should arise, these relief valves open in response to release any excess fluid accumulating within them before any possible component damage takes place.

4. Applications of Hydraulic Systems

Hydraulic systems have become an indispensable resource across various industries due to their many advantages and versatility, with prominent examples being found here:

Construction and Heavy Machinery

Hydraulic systems power an assortment of construction machinery such as bulldozers, excavators, loaders and cranes requiring powerful force as well as precise control in terms of hydraulic power delivery and precise management for optimal performance.

Hydraulic systems play a vital role in manufacturing machines to perform various metal forming, stamping and pressing operations that require high levels of precision. Hydraulic systems make possible the creation of intricate parts with greater ease than ever.

Aerospace Hydraulic systems play an integral part of aerospace industries by controlling landing gears for aircrafts and flaps on control surfaces as well as control surfaces themselves to provide efficient actuation of critical functions.

Hydraulic systems play an integral part of modern vehicles, being employed to power steering, brake systems and automated transmissions that enhance both safety and comfort.

Agriculture

Machines for farming such as combine harvesters and tractors rely heavily on hydraulic systems for lifting, steering and powering attachments – including their lifting mechanism, steering mechanism and attachment powering features.

Mining

Mining operations require hydraulic systems for equipment like hydraulic drills, shovels or underground machines which must meet stringent performance and precision criteria. In mining operations hydraulic systems often play an integral part.

Hydraulic systems have long been utilized as essential marine applications, used to maneuver mechanisms, winches and anchor handling equipment efficiently and ensure safe vessel operation.

Hydraulic Systems in Oil and Natural Gas

In the industry of oil and natural gas, hydraulic systems are frequently employed for tasks like drilling offshore platform operations and pipeline maintenance.

Robotics

Industrial robots utilizing hydraulic systems tend to use them because of their durability and precision; industrial robots utilize hydraulic actuators for tasks like welding, material handling and assembly.

4.10. Entertainment Hub For use in entertainment industries such as theme parks or theaters, hydraulic systems can also provide special effects such as moving sets or animatronics to create the necessary special effects such as animatronics.

5. Challenges and Considerations

Hydraulic systems provide many advantages; however, they also pose certain hurdles and issues:

Hydraulic systems can become susceptible to fluid leakage over time. Proper inspection and maintenance practices are necessary in order to minimize this possibility and mitigate it as much as possible.

Environmental Implications Hydraulic fluids used in these systems could pose environmental threats if handled or disposed of incorrectly; there has been increasing attention given to using eco-friendly hydraulic fluids in recent years.

Maintenance for hydraulic equipment is key to its reliability, so regular inspections, replacing of fluid with fresh supplies and servicing components is vital to avoid breakdowns and costly repairs.

Hydraulic systems produce heat during operation. Any excess heat must be released so as to avoid overheating which could damage components or diminish effectiveness of the operation.

Noise

At times, hydraulic systems may produce noise that disrupts specific situations and require remedial actions to limit it. Noise-cutting measures could therefore become necessary.

Cost

While hydraulic systems offer long-term savings, initial setup and maintenance expenses can be substantial; this should usually be offset by their increased efficiency and longevity.

Conclusion

Hydraulic systems have revolutionized various industries with their unsurpassed power control, reliability, and stability. Their ability to transfer force effectively makes them essential in applications spanning from construction machinery and heavy vehicles to robotics and aerospace applications.

Despite any issues related to maintenance costs or environmental concerns associated with hydraulics systems today, their impact remains an integral one of modern industry and engineering and contributes to improved efficacy and effectiveness – while technology develops further the role that these hydraulics will continue to play as machinery engineers advance further and develop.